Note: This is an old and unmaintained article. New ventilation article is HERE.

————— DRAFT —————

Ventilation in sauna is critical, more so than in our homes or offices. One or a bunch of people closed up in a tiny room like a sauna results in very high levels of exhaled CO2 that is unhealthy and must be removed. Removal of excess CO2 is the primary purpose of ventilation. Removal of odors and particulate matter created when water is thrown on the stones is important as well. Lassi Liikkanen points out that ventilation is necessary also for removing excess humidity during sauna or else successive throws of water on the stones will over time result in too much humidity.

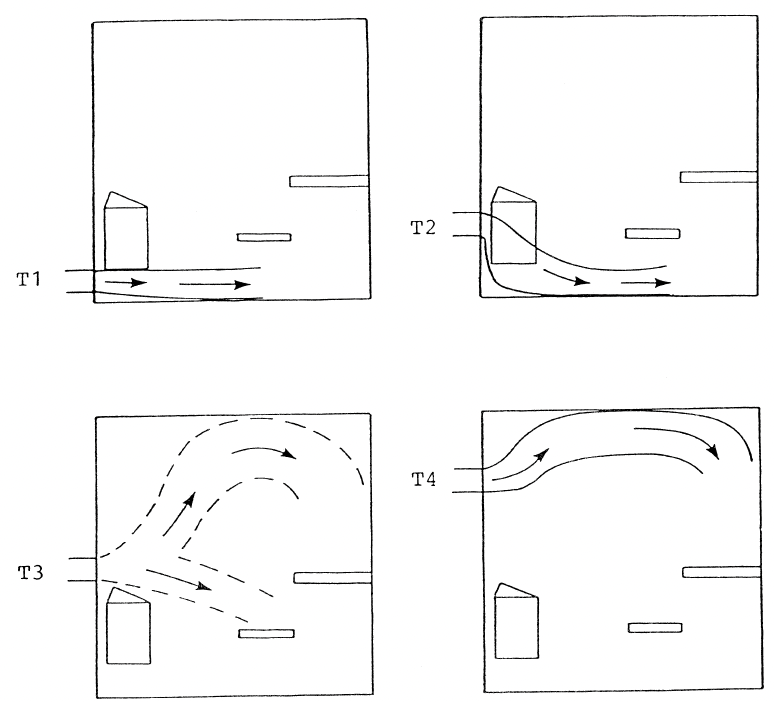

Bad ventilation is likely the number one problem plaguing saunas across North America and why it’s said that 90% are bad and the rest are worse. Fortunately proper ventilation is quite simple. In Finland, Sweden and most of elsewhere a good sauna builder will provide a fresh air supply above the heater, mechanical exhaust below the foot bench, it works well and everyone is happy. It’s much more complicated, and thus confusing, in North America.

For more on why proper ventilation is so important: Ventilation – Finding Good Pure Air

Ventilation Options

There are three psuedo-viable schemes for ventilation in electrically heated saunas;

1) Natural Convection Low to High – Fresh supply air entering below the heater (or sometimes below the door or behind the heater) with exhaust in the ceiling or, as recommended by Tylö-Helo, 24” above the floor. This is the predominant system used in the U.S. and North America, is recommended by Tylö-Helo and other manufacturers for their North American heaters and is what online searches in English turn up.

2) Mechanical Low to High – Same as above but using a duct blower for the exhaust instead of relying on natural convection.

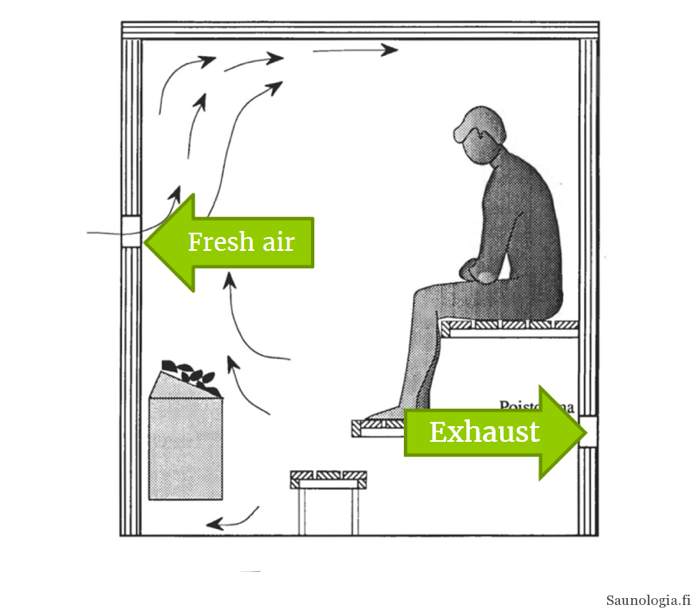

3) Mechanical High to Low – Fresh supply air entering above the heater and mechanical exhaust below the foot bench (typically an inline duct blower). This is the predominant system used in Finland and Europe.

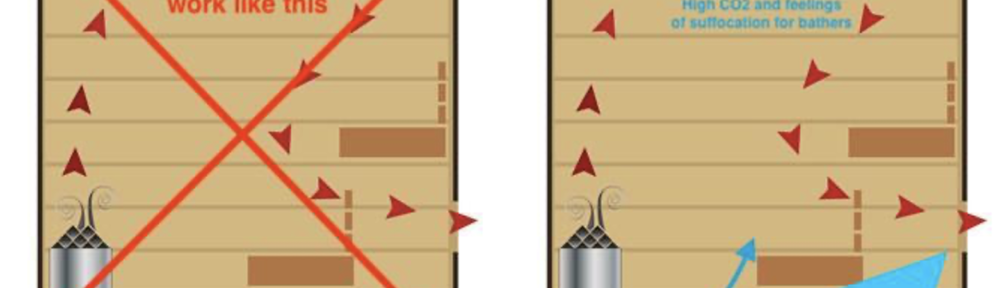

The problem is that neither #1 nor #2 work. Neither provides good ventilation or even any ventilation at all. Physics says that they will not work and studies by VTT in Finland prove that they don’t work. Research I’ve done in our sauna support this and indicate that both of these result in high, unhealthy and uncomfortable levels of CO2 which is why people so often complain about stuffiness or feeling dizzy in North American saunas. And this is why sauna builders in Finland don’t do this and why Tylö-Helo and others don’t recommend it.

Mechanical High to Low, #3, does provide good ventilation. Physics says that it should and studies by VTT say that it indeed does*. In our sauna it results in proper low levels of CO2 and a much better sauna experience.

Understandably, sauna builders I’ve talked to in Finland and Sweden say to use #3. VTT has recommended mechanical high to low since their research in 1992 showed it the best and realistically only good option. Tylö-Helo and other heater manufacturers recommend mechanical high to low outside of North America and online searches in Finnish, Swedish and German show #3 as the recommended solution. Research in our own sauna has indicated that the only way to maintain sufficiently low, healthy and comfortable levels of CO2 is also mechanical high to low.

There are four reasons for this.

1 – Cold Air Sinks. Cold air entering below a heater does not flow up in to the heater as many people wish. A little flows up in to the heater, a little more rises up to envelope bathers feet in cold air, but the majority flows across the floor and then out the exhaust without providing any benefit.

On the other hand, fresh cold air entering above the heater will get entrained in the upward rising heat and disperse throughout the sauna along with that heat.

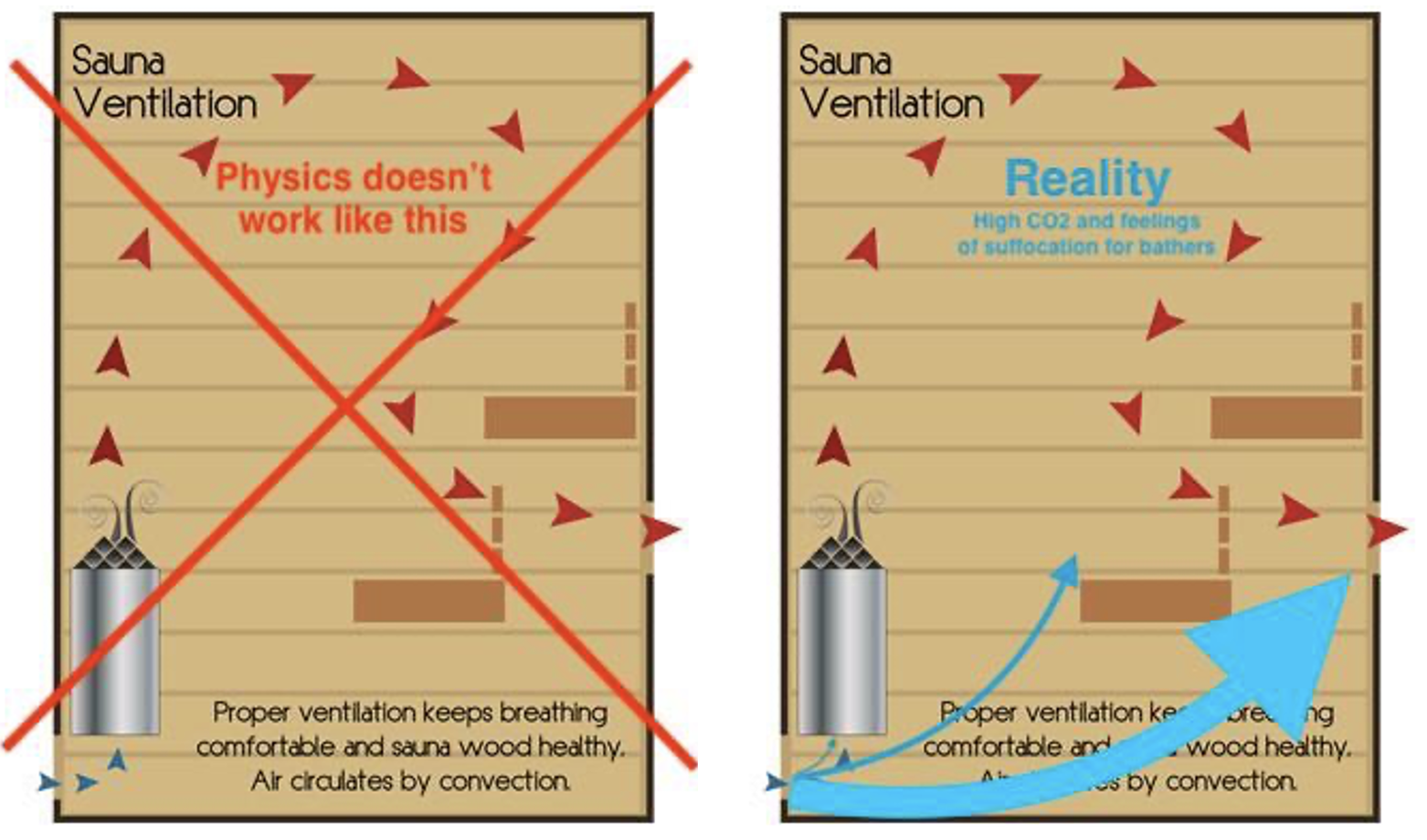

This chart from the 1992 VTT study sums it up well. T1 and T2, which are the recommendations of North American heater manufacturers, simply flow across the floor. T3 partially works but not well. T4 is the only supply solution that results in proper ventilation for occupants.

2 – Natural Convection Is Unreliable. Any kind of natural convection in an electrically heated sauna is unreliable and rarely if ever results in enough air flow for a healthy environment and sometimes zero airflow. In a wood fire heated sauna the stove itself provides sufficient exhaust airflow but electric heated saunas (and wood fire saunas with external combustion air) need a blower to sufficiently exhaust stale air.

3 – Low To High Is Undesirable. Any Low to High Ventilation, natural convection or mechanical, that pulls cooler air upwards often results in lower temps for the foot bench. The most critical problem here is that foot benches in these saunas then do not maintain high enough temperatures (+55°c / +130°f) to kill bacteria and mold. And, while not as important as maintaining healthy CO2 levels or killing bacteria, this also results in cold feet and legs.

High to Low Ventilation that pulls warmer air downward does a better job of removing exhaled CO2, is much more likely to maintain the temperatures needed for killing bacteria and mold, and results in warmer and more comfortable legs and feet. This is why everything I can find in Finnish, Swedish or German recommends supply above the heater.

4 – Ceiling Exhausts Kill Löyly – An exhaust in the ceiling (or really anywhere much above the foot bench) exhausts steam and heat, quickly killing any löyly.

Confusion, Controversy And A Problem

Given the overwhelming benefits of Mechanical High to Low Ventilation (#3) and the critical drawbacks of the other two, why would anyone recommend #1 or #2?

And, why do Tylö-Helo, Harvia and others recommend #3 everywhere but North America? Last I checked physics is the same in North America as in Finland.

The only viable reason I know of for recommending either of the first two, for supply air below the heater instead of above, is to provide cooling for the heater itself. And this indeed appears to be the case. Electric heaters sold in North America often have an HL (High Limit or Overheat Protection) switch with what seems a very low set/trigger temp. The cooler air from a vent below the heater is needed to cool either the heater or HL switch as otherwise it will trip and shut off the heater until it cools down below the set point.

Heaters sold outside of North America do not appear to need a lower vent to cool the heater or HL probe nor do they have problems with these tripping unnecessarily. Importantly, electrically heated saunas outside of North America also get much hotter than saunas in North America (because of UL restrictions) so if anything should have a greater need for this lower vent if it’s needed for the heater itself.

There is clearly a major difference in heaters sold in the U.S. and those sold in Europe and it’s a difference that is a significant disadvantage to U.S. consumers.

That I can think of there are only two reasons for the High Limit switch to trip at such a low temperature for U.S. heaters; 1) A UL requirement or 2) Low quality manufacturing. Both are reasonable.

Underwriters Labs, UL, does a lot of good and their recommendations, at least on the surface, result in a safer world for all of us. We do know that they require a very low overall sauna temp of 90°c (or actually well below this) for electric heaters so it is not unreasonable to assume that they also have other regulations that result in manufacturers including the high limit or overheat protection switches that are causing our ventilation (and other) problems**.

U.S. consumers have a reputation for desiring lower cost over better quality and of not demanding higher quality and this would not be the first time that lower quality products are sold to U.S. consumers vs those sold elsewhere. Lower quality have a lower manufacturing cost that results in higher profits.

I have not yet been able to verify either of these. In my discussions with UL I have yet to see anything from them that would require the low HL switch temp. Heater manufacturers insist that those sold in the U.S. are the same quality and often the exact same heaters as those sold in Finland and Europe (except for anything needed to meet local code requirements). Yet, there is a very clear difference.

To summarize, it appears that the very low set temp for the HL switch causes a need for supply air to cool the heater or HL sensor. Manufacturers then chose a solution to provide this cooling to the heater rather than provide critical ventilation to occupants resulting in high levels of CO2 and other problems for North American saunas.

Ultimate Solution

We need to be able to use the same ventilation as Finland and others with fresh air entering above the heater. This will likely require either changes from UL, changes by manufacturers or both to eliminate the need for cooling the heater or HL sensor.

Ventilation For North American Sauna

Until we have different heaters and can do the same ventilation as others we’ll need to make some compromises. The following applies to electrically heated saunas and most wood stove saunas that are loaded and receive combustion air from outside of the sauna hot room (typically the changing room). Wood stove saunas with loading and combustion from within the hot room have some slightly different criteria.

Convection Doesn’t Work Well – If you have an electrically heated sauna you realistically need mechanical ventilation using an electrically powered duct blower or similar.

15-25 CFM Per Person – We want to keep CO2 levels for bathers below 700 ppm and ideally below 550 ppm. Or not more than 150-300 ppm above outside. A general recommendation is a minimum of 15 CFM (25 m³ / hr) per person though DIN1946 says that 18 CFM are needed. Due to higher levels of CO2 in exhaled breath of active people however gyms often require 20-25 CFM per person so sauna’s may similarly need somewhat more than 15-18 CFM but this needs more study. Initial measurements in our sauna show a need for somewhere between 20 and 25 CFM per person to keep CO2 levels at appropriate levels. It’s important to note that too much ventilation can lessen löyly by removing too much heat and moisture so the amount of ventilation may need careful balancing.

Fresh Air Supply ABOVE The Heater – Air for ventilation needs to enter in a way that it sufficiently mixes with the hot air and circulates to bathers faces. A single vent above the stones, about 1/2 to 3/4 of the distance from the top of the stones to the ceiling should usually work fairly well.

Heater Cooling Supply Below Or Behind The Heater – A secondary supply may be needed to cool the heater or HL probe. We want as much fresh air entering the sauna as possible to come from the higher supply above the heater however so that it will benefit bathers. So, this lower vent should be adjustable so that only enough air to provide whatever cooling of the heater or HL probe comes from this supply while the rest comes from the upper supply.

Mechanical Exhaust Below The Foot Bench – This exhaust vent should usually be on the wall opposite the stove and under the foot bench. This will help to pull warmer air down past bathers feet and result in a much more comfortable experience.

5 Effective CFM is better than 20 Ineffective CFM – If your heater has difficulty keeping up with cold fresh supply air then reduce the flow rather than move the vent lower. 5 CFM entering above the heater that helps to reduce CO2 is much more beneficial than 20 CFM entering below the heater that does not reduce CO2 levels and adds to cold feet.

Clearing Exhaust In/Near Ceiling? – (Maybe) Include a clearing exhaust in or near the ceiling opposite from the stove and supply air. After the day is done this exhaust can be opened (with the stove still heating) with the blower running for about 15 minutes to clear the sauna of accumulated moisture which will help with keeping mold and bacteria at bay. HOWEVER, I’m not sure that this extra vent is necessary. If you have a supply vent over the heater and mechanical exhaust on the opposite side below the foot bench then when you’re done with your sauna for the day you may be able to simply leave it going (heat and ventilation) for 15-30 minutes and get the same result. It should effectively exhaust excess moisture and, assuming at least 55°c at the foot bench, kill most bacteria and mold. This needs more study.

Duct Design – The smaller the duct the more noise from airflow (and the more static pressure) so somewhat larger is better. 4” round (13 sq inches) for up to 50 CFM, 6” (28 sq inches) for up to 140 is good. Make sure that the blower and nearby duct is mounted w/ perf strap or isolation hangers and that neither the duct nor blower contact any framing to prevent vibration noise from coming inside your sauna. A silencer (such as from Fantech) installed between your vents and blower can reduce noise a bit more if you want ultimate quiet though proper duct design and installation should result in a very quiet and possibly silent system without it.

Use Hard Duct – Flex duct results in high static pressure, often cannot tolerate the heat of a sauna and should not be used for exhaust ducts. Stretched tight and installed properly, it’s OK for supply air (and may be a good idea in really cold environments as insulated flex doesn’t have the condensation problems that metal duct does).

Blower Size – Blowers are typically rated for how many CFM or m³/hr they deliver. The marketing material will typically only publish what is called free air flow which is the blower without any ducting or wall caps that can reduce airflow. These things that reduce airflow are called Static Pressure. If you are familiar with Static Pressure then you should calculate the static pressure losses in your fresh air supply AND exhaust ducts and choose a fan that delivers the desired CFM @ xx” Wg. However, in most cases you’d likely be safe to simply choose a blower that has 150-200% of your desired airflow. A variable speed blower and controller are highly recommended.

Control – Control can be a simple rotary speed controller from Fantech. However, controlling the exhaust blower with something like a Lutron Casetta provides a number of benefits. First is that it will allow for speed control of the blower so that ventilation can be adjusted to balance CO2 removal and heat. It can have a timer to automatically turn ventilation off a certain amount of time (15 minutes?) after sauna is done for the day. It can be programmed to turn on for some bit of time each day (20 minutes every morning at 7a ?) to prevent musty stale air when the sauna is not in use. On the latter it’s best if this can be done with a smart system of some sort so that it only does this automatic ventilation when supply air humidity will not be too high.

We’ve also played with slowing the blower a bit when the heater is off (heaters turn on and off constantly during use) while using the sauna which has proven very effective in reducing how much cool air bathers feel when it’s very cold (like -20°f) outside. This is fairly easy to do with typical home automation systems such as Control4.

Ventilation – Extra Stuff

Multiple Smaller Vents Might Be Best – Ten 2” supply vents (28 sq inches) above the stones might work better than a single 6” as it will result in better mixing (better hot:cold ratio so less of the colder supply air will sink to the floor). Similarly four 3” exhaust vents spread out below the foot bench might do a better job of removing excess CO2 for all bathers than a single 6” that might work well for those directly above but not so well for those further away. For the best even distribution on the latter the vent holes should be slightly smaller near the duct and larger farther away.

I’m experimenting with various configurations in our sauna and the results have been quite enlightening. The current winner for supply is to have about half the supply flowing downward towards the heater and then 5 2” holes horizontally closer to the ceiling. This results in the best mixing and lowest CO2 for different temps and makes for an overall much better sauna experience.

[photos]

This IR image shows why. You can see how far down the colder air goes. Eventually though it is warmed enough that it begins to rise rather than continue flowing down to the floor as it would if this vent were nearer the floor. Flowing down like this also aids mixing – if instead it flowed outward as is typical then some portion would flow through the rising heat and might be felt by bathers. A baffle on the supply vent might also help mixing.

Another alternative is a flapper vent cap like those used where exhaust vents exit a house. Holes can be cut in the upper (sloped) face so that when ventilation is OFF the heat rising from the heater will flow up through these holes (and not in to the duct). When ventilation is ON the flap will open and fresh supply air will flow downward towards the heater where it can mix with the rising heated air.

Conditioning Fresh Air Supply – Bringing in very cold outside air for ventilation can be a problem. Sometimes the heater cannot keep up and keep the sauna at our desired temperature and there can also be problems with the air not mixing fully with the hot air and so bathers sometimes feel some colder air mixed with hotter air. Reducing the amount of fresh air is one solution but this can result in too high of CO2 levels. There are three options that I can think of for heating this incoming air; 1) An electric heater in the duct (such as an Electro Industries EM-WX01), 2) An ERV/HRV/CMV that uses the heat in the exhausting air to heat the incoming supply air or 3) A duct running up the wall behind the heater. There are also hydronic duct heaters for situations where there is a supply of hot water from a boiler.

Maybe Pre-Warm The Supply Air – Bringing supply air in to the hot room below the heater and then having a metal duct run up the wall behind the heater to nearer the ceiling where it is exhausted will pre-warm the supply air and may result in better mixing, better CO2 removal and a more comfortable sauna experience. This isn’t critical but something to consider. It may also be possible to capture some rising heated air from the heater to mix with this colder supply air within the duct before it’s supplied to the room which would result in better overall mixing.

Filtration – Little is mentioned about filtration of incoming air. Generally it is likely not needed. However, during some wildfires in Canada last year we had some significant ambient smoke so I had to rig a MERV-16 filter on to the outside inlet as otherwise the air inside the sauna was quite unhealthy. People in areas with poor air quality may find that a filter on incoming air makes for a better experience. Typically a MERV-13 should be sufficient though a MERV-15 or higher might occasionally be needed.

Supply Side Blower – Ventilation in a space is traditionally accomplished with a mechanical blower on the exhaust side and the supply side being passive airflow (exhaust blower creates low pressure in space that then pulls air in through the passive supply duct). Adding a blower to the supply side might help in some situations and could also result in better mixing. Supply side only (passive exhaust) is also a possibility but what happens with airflow in the sauna becomes more complicated. The end result could be better or could be much worse.

Measurement – Ideally we want to keep CO2 at bathers faces below 700 parts per million and ideally below 550 ppm. Measuring is difficult because CO2 meters don’t work well at sauna temps. We are working with a company on a solution but it’s still a ways out. In the interim there are a couple of options if you want to see how your own sauna does. First is to place a CO2 meter somewhere that temps remain below the max temp for the device (typically 60°c). In our sauna that’s on the platform below the foot bench and a bit away from the heater. Many or most home devices do not provide accurate readings however those from CO2meter.com, IQ Air, and Awair (version 2 or later) have proven reliable. Avoid Foobot. Note that the actual CO2 level at bathers faces is generally a bit higher so adding 10-20% to readings might be good.

The second alternative is to heat your sauna to a temp that is safe for your meter to be closer in proximity to bathers faces and then doing three rounds of ‘cool sauna’. It’s important to find friends willing to do this so that you have as many people as you’d normally have. CO2 is multiplicative so 4 people exhale about 4x as much in to the room as one person.

Still To Learn:

We see extremely high particulate matter (1.0, 2.5 and 10.0) when ladling water on to the stones. Part of this and possibly all of it is bits of stone breaking off and disbursing with the steam. I’d guess some of it is also from the calrods. Neither is good. As ventilation has improved so has this. Moving the fresh air supply to over the heater had very dramatic effect on lowering PM and better mixing using different hole patterns has helped as well.

We’re still trying to figure out a good reliable way to measure CO2 near bathers faces during a sauna session. It’s easy to do at lower temps like 60°c but not so much at 90°c which is above the temp range for most meters. Airflow will be different then too so why I’d like to find a good way to measure it.

* Thanks to Lassi Liikkanen for having VTT publish this research online.

** Just as with some overly strict laws, overly strict UL regulations can cause more problems than they solve. Saunas limited to 90°c often have problems with bacteria and mold in the foot benches and elsewhere because the sauna cannot get hot enough to kill them. The lower temps also may not result in the health benefits that higher temp saunas in Europe provide. As well, to get around the low limit, many people place the thermostat temperature probe for electric heaters in a location that allows the sauna to achieve higher temps than the 90°c that UL states. One problem with this is that it can no longer properly regulate the temperature as a thermostat outside of North America can. If a thermostat in Finland says the sauna is 90°c then you know it likely is, in North America it may well be much hotter.

The lower temperature setting for the High Limit Switch causes numerous problems. Chief among these is that it’s caused manufacturers to recommend bad ventilation strategies that result in unhealthy levels of CO2 in U.S. saunas.