Steam added to stale air is just that, steam added to stale air, it is not löyly

Proper ventilation is critical for a sauna and for löyly – no proper ventilation, no löyly.

Proper ventilation truly gives life to a good sauna experience.

Unfortunately most of the information available in English is inaccurate. It confuses heater cooling and ventilation for humans in electric saunas, and relies on bad or outdated information for both electric and wood. The result is that saunas in North America almost universally have poor ventilation. Wood fired saunas have air for combustion and little or none for ventilation, electric have air to cool the UL mandated but unnecessary heater high-temp sensor but little or none for ventilation for human occupants.

Bad ventilation is likely the number one problem plaguing saunas across the English speaking world and why it’s said that “90% of saunas in North America are bad, and the rest are worse”.

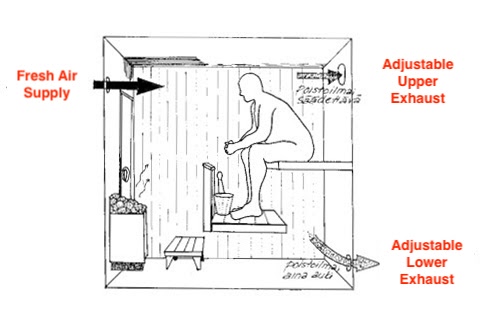

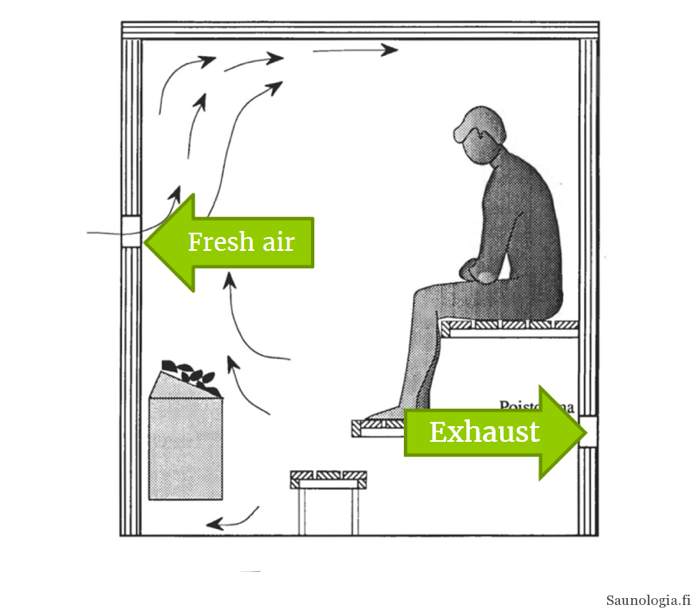

Fortunately proper ventilation is not difficult. In Finland, Sweden and most of elsewhere a good sauna builder will provide a fresh air supply (typically above the heater), and for electric a mechanical exhaust below the foot bench, it works well and everyone is happy. It’s much more complicated, and thus confusing, in North America.

This is an addendum to Trumpkin’s Notes on Building a Sauna which should be read for further understanding. For further information on measuring temp, humidity and CO2 see ‘Thermometers and Measurements’ in the menu above.

If you want to insure the best possible outcome for your sauna and ventilation then I highly recommend Lassi Liikkanen as a consultant.

TL;DR Brief

Proper Ventilation for Wood Heated Saunas Fed from Inside the Hot Room:

For Wood Heated Saunas Fed from Inside the Hot Room I think the ideal is three adjustable fresh air supplies; 1) above the heater, 2) below the foot bench on a wall opposite the heater and optionally, 3) near the floor behind/below the heater. This combination of Opt 1 and 2 below will allow for varying adjustments to find the best ventilation for a particular sauna in a particular environment on a particular day.

Opt 1 (Downdraft)**:

- Fresh Air Supply For Bather Ventilation Above The Heater – This is what provides fresh air for bathers and more importantly for removing CO2, excess humidity and other contaminants. This should be located above the heater; 1) On the wall above a point halfway between the top of the stones and the ceiling or 2) In the ceiling directly above the heater. This should be adjustable, ideally come from outside and include a back flow device. Incorporating a bit of updraft duct and/or a mechanical blower may be recommended.

- Air Supply For Heater Combustion Near The Floor – This provides excess combustion air for the fire and should be adjustable.

- Natural Exhaust In Opposite Corner Near Or In Ceiling – This is opened after the day is done to allow excess moisture to be exhausted and is usually located near a corner furthest from the heater.

Opt 2 (Circulating)**:

- Fresh Air Supply Below The Benches Opposite The Heater – These provide combustion air and hopefully good ventilation for bathers. This is Lassi Liikkanen’s improved version of the traditional ventilation used in wood heated saunas in Finland. By moving the fresh air supplies to the opposite side of the space there is better potential for mixing to provide better ventilation for bathers. Two to Four supply vents located under the benches, possibly on two adjacent walls to account for changing wind conditions.

- Natural Exhaust In Opposite Corner Near Or In Ceiling – This is opened after the day is done to allow excess moisture to be exhausted and is usually located near a corner furthest from the heater.

Proper Ventilation for Electric Heated Saunas and Wood Heated Saunas Fed from Outside the Hot Room (Mechanical Downdraft):

- Fresh Air Supply For Bather Ventilation Above The Heater – This is what provides fresh air for bathers and more importantly for removing CO2, excess humidity and other contaminants. This should be located above the heater; 1) On the wall above a point halfway between the top of the stones and the ceiling or 2) In the ceiling directly above the heater. This should be adjustable, ideally come from outside and include a back flow device. Incorporating a bit of updraft duct and/or a mechanical blower may be recommended.

- Air Supply For Cooling the Heater High-Temp Sensor Behind/Below The Heater – For heaters that have this sensor (typically all that are UL Listed) this provides air to cool the sensor to prevent the high-temp limiter from nuisance tripping. This should be adjustable and only just enough air flow to keep the sensor from tripping. Note: If UL update UL 875 to conform to EU standards then this supply will no longer be necessary.

- Natural Exhaust In Opposite Corner Near Or In Ceiling (Optional) – This is opened after the day is done to allow excess moisture to be exhausted and is usually located near a corner furthest from the heater. Alternatively, leave the exhaust blower running for about 2 hrs which will do a better job of clearing moisture. Note: We’ve had Mechanical Downdraft in our sauna for over 3 years now (since 2020) and have found no need for this exhaust. Running the blower for a couple of hours is more than sufficient.

- Mechanical Exhaust Below The Foot Bench – This s/b about 20-25 CFM per person plus 15-25 CFM for the heater HT sensor (so 100-125 CFM for a 4 person sauna). An inline duct blower such as from Fantech is usually the best option.

* Note: Natural ventilation does not work well in electrically heated saunas and significantly increases stratification which combined significantly lessen the sauna experience. These saunas should always have mechanical downdraft ventilation if at all possible.

** Note 2: The above does not apply to heavy steel stoves such as Kuuma or Nippa that do not produce a good convective loop. A good convective loop is critical for these to work.

Note 3: Ventilation in a sauna is designed for normal levels of CO2, bacteria and other gook. Excessive movement such as exercising or yoga can produce much greater amounts of CO2 (≈8x vs someone sitting still?) and levels beyond what standard ventilation can effectively exhaust. Similarly, high bacteria levels from someone not showering/rinsing well before entering or wearing textiles beyond a minimal swimsuit can be greater than normal ventilation is designed to handle.

Head to Toes Temp Difference – A key goal of sauna is to be heated evenly head to toes and this is the primary element behind the saying ‘Feet Above The Stones’. We ideally want no more than about 15°c head to toes temp difference and any more than 25°c is generally deemed unacceptable. In electrically heated saunas (and wood heated fed from outside the steam room) natural convection results in an INCREASE of about 8-12°c while mechanical downdraft results in a DECREASE of about 7-15°c. This is a key reason why Mechanical Downdraft is so strongly recommended.

For example, in our sauna, natural convection results in a head to toes temp difference of about 40°c which is quite bad. Mechanical downdraft results in a difference of about 16°c which is ideal.

Continue reading for why ventilation is so critical, why the above is the recommended ventilation used in Finland and elsewhere and more detail on the above. If you just want to get to it then skip down to Proper Ventilation For North American Saunas.

Important Note (Jan 2024): UL are expected to update UL 875 to conform to EU standards in the coming months (or years). This is VERY GOOD NEWS. This will eliminate a lot of confusion in North America. This should eliminate the need for an air supply behind/below the heater to cool the over sensitive high limit sensor, allow proper placement of the thermostat sensor over the sitting bench and allow for temps higher than 90°c. Overall this will be a big improvement for North American sauna users and builders. More to come…

Table Of Contents

- The Need For Ventilation (Wood & Electric)

- Wood vs Electric (Wood & Electric)

- Ventilation Options For Electrically Heated Saunas (Electric)

- More (for those who want to geek out on this topic) (Electric)

- Two Temperature Sensors In North America (Electric)

- Confusion, Controversy and Problems (Electric)

- Proper Ventilation For North American Saunas (Electric)

- Using Ventilation Properly

- Ventilation – Extra Stuff

- Troubleshooting

- Ventilation Options For Wood Burning Heaters (and why Finns are changing it) (Wood)

The Need For Ventilation

Ventilation is all about our breathing and in a sauna this is critical, even more so than in our homes or offices. One or a bunch of people closed up in a tiny room like a sauna quickly results in very high levels of exhaled CO2 that is unhealthy, harms the sauna experience and must be removed. Removal of excess CO2 is the primary purpose of ventilation.

Post workout sauna in a sauna with poor ventilation may actually do more harm than good due to the resulting high blood pCO2 that reduces rather than enhances recovery.

Removal of various other odors, VOC’s and pathogens is important as well. Flatulance is normal, but not something we want hanging around. If someone has a developing Flu or Covid we want the pathogens they exhale to be removed as quickly and effectively as possible. As of Feb 2023, Covid is still a concern and one of the best ways to know if an occupied space has proper ventilation is to measure CO2 to insure that it’s at least under 700 ppm and ideally below 550 ppm.

When we throw water on the stones to create steam we also create particulate matter – PM1.0, PM2.5 and PM10. I’ve measured this in my and one other sauna and presume it happens in many others if not all. My guess is that this is mostly bits of the stones but likely also includes some of the steel from calrod heating elements or iron from wood heaters. It’s important that this PM be removed fairly quickly as breathing it is quite unhealthy. (Note: We know from studies that the health benefits of sauna outweigh the brief exposure to PM when this PM is removed quickly. That may not be the case if the PM is not removed quickly.)

The air movement provided by proper ventilation also helps to eliminate problems of windows fogging.

Lassi Liikkanen points out in his excellent “Secrets Of Finnish Sauna Design” that ventilation is necessary also for removing excess humidity during sauna or else successive throws of water on the stones will, over time, result in too much humidity. In his book ‘Finnish Sauna’ Allan Konya similarly talked about the importance of good ventilation for controlling humidity, pointing out that just as we want cycles of hot/cold/hot/cold we also want cycles of humid/dry/humid/dry. After throwing water on the stones we then want that humidity removed so that overall humidity goes back down to where it was before so that each successive throw results in the same level of humidity increase and same comfortable effect. Allan’s book was published in English 35 years ago – the need for good ventilation is not new.

Cooler air also insures that the elements on an electric heater turn on frequently enough to keep the stones sufficiently hot to produce good steam. Without this cooling air the sauna can remain quite hot so the heater does not turn on frequently enough.

The door opening DOES NOT provide ventilation. If it did then you would also replace all of your heat with cooler outside air. Without good ventilation, however much heat there is in your sauna above outside temps, that is how much CO2, Pathogens and other stuff there is.

Disclaimer: I am not an engineer nor doctor. Nor any kind of expert on sauna. The following is simply a bunch of notes on what we learned building our sauna and that we wish we’d known much sooner. Use at your own risk. I strongly encourage everyone reading this to do further research on all of these topics and in particular to read Lassi’s book (listed at the end). And if there is anything inaccurate below please let me know so that it can be corrected.

For more on why proper ventilation is so important: Ventilation – Finding Good Pure Air.

Wood Burning vs Electric

All saunas need ventilation for human occupants (bathers); to remove CO2, excess humidity and other undesirable stuff in the air and replace it with fresh clean air.

The difference is how exhaust is accomplished. Wood burning heaters act as a powered exhaust. They can produce anywhere from 100 to 600 CFM of exhaust airflow to pull stale air (CO2, humidity) out. This then creates low pressure that in turn pulls fresh air in through fresh air supply vents.

An electric heater does not do that nor does a wood burner that is fed from and receives combustion air from outside of the sauna hot room. So these saunas need a mechanical exhaust blower to exhaust the stale air.

Much of the following focuses on the latter but many of the concepts discussed also apply to wood burning heaters fed from inside the sauna. Towards the end is a section specific to wood burning.

Ventilation Options For Electrically Heated Saunas

This applies as well to wood burning saunas that are fed from and receive combustion air from outside of the sauna hot room.

Heater Cooling vs Ventilation

Supply air entering below the heater or behind the heater is for heater cooling in North America and elsewhere that follows similar UL guidelines. This DOES NOT provide ventilation.

For reliable ventilation in a sauna with an electric heater the fresh supply air should enter ABOVE the heater and exhaust should be powered mechanical exhaust (ideally from below the foot bench on the wall opposite the heater – more below).

Three Schemes

There are three psuedo-viable schemes for ventilation in electrically heated saunas;

- Natural (Convection) Updraft – Fresh supply air entering below the heater (or sometimes below the door or behind the heater) with exhaust in the ceiling or, as recommended by Tylö-Helo in the U.S., 24” above the floor on the opposite wall. This is the predominant system used in the U.S. and North America, is recommended by Tylö-Helo and other manufacturers for their North American heaters and is what online searches in English usually turn up.

- Mechanical Updraft – Same as above but mechanical (typically an electric duct blower) for the exhaust instead of relying on natural convection.

- Mechanical Downdraft – Fresh supply air entering above the heater and mechanical exhaust below the foot bench (typically an inline duct blower) or below the door. This is the system recommended in Finland and elsewhere.

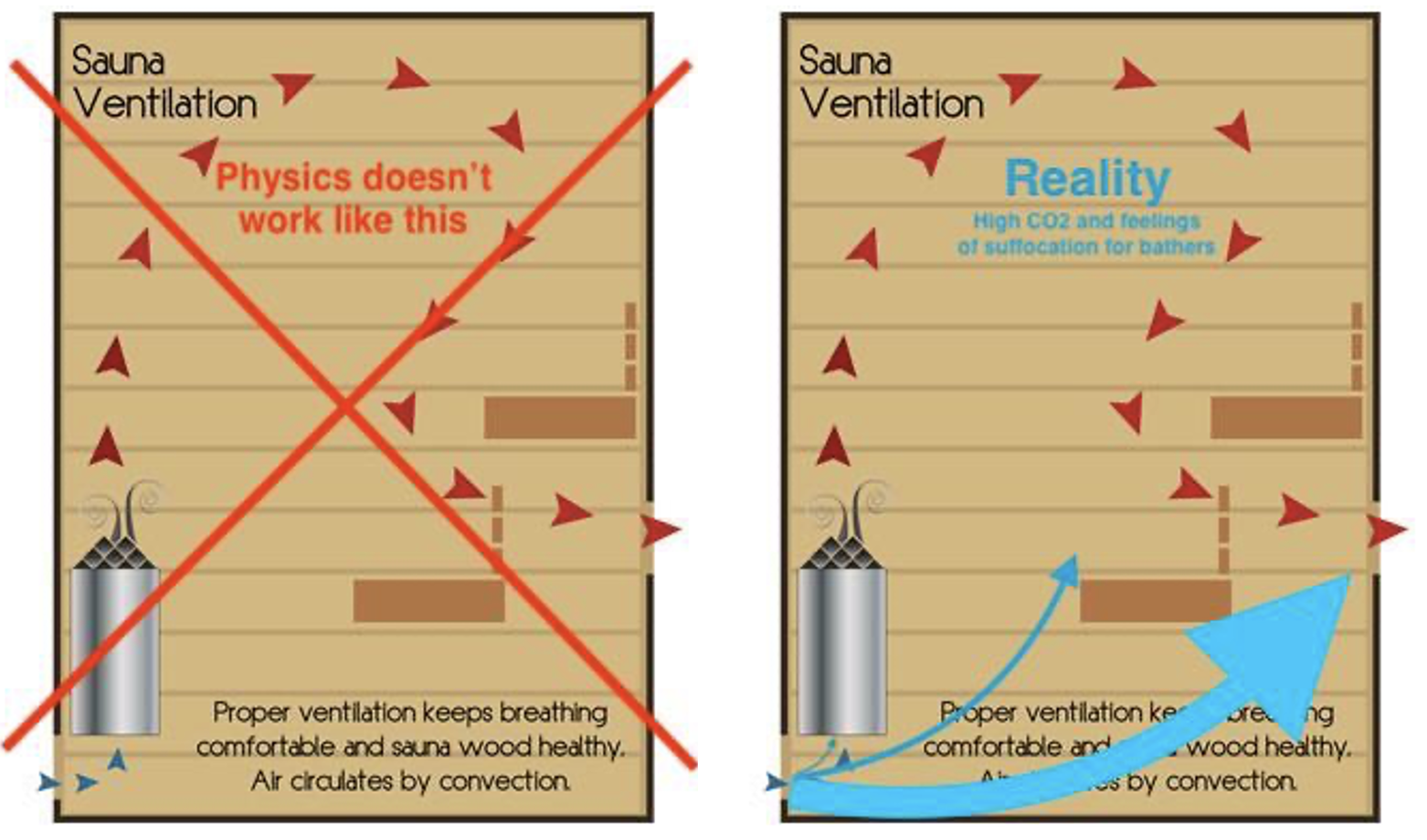

The problem is that neither #1 nor #2 work. Neither provides good ventilation nor even any ventilation at all. Physics says that they will not work and studies by VTT in Finland prove that they don’t work*. Research I’ve done in our sauna support this and indicate that both of these result in high, unhealthy and uncomfortable levels of CO2 which is why people so often complain about stuffiness, feeling dizzy or sudden anxiety in North American saunas. These also increase stratification and ‘cold feet’.

Mechanical Downdraft, #3, does provide good ventilation. Physics says that it should and studies by VTT say that it indeed does. In our sauna it results in proper low levels of CO2, lower PM, proper levels of moisture and less heat stratification – and a much better sauna experience.

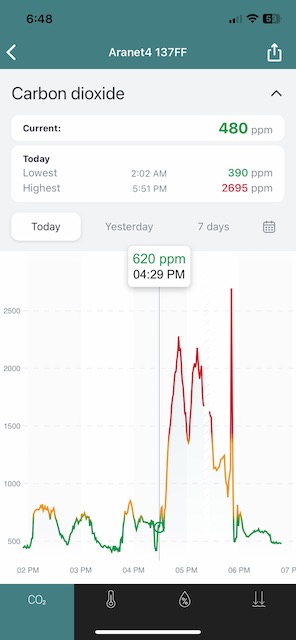

To give you an idea of how much of a difference this makes. Here we were first in a sauna using Mechanical Downdraft. You can see that CO2 maxed out at about 700 ppm which is good. At 4:30 we moved to a sauna with natural convection. CO2 levels here were much higher and this was also very noticeable in our experience – a bit more difficult to breath, less comfortable and even though a lower temp we couldn’t stay in as long.

Understandably, sauna builders I’ve talked to in Finland and Sweden say to use mechanical downdraft. VTT has recommended mechanical downdraft since their research in 1992 showed it the best and realistically only good option. Tylö-Helo and other heater manufacturers recommend mechanical downdraft outside of North America and online searches in Finnish, Swedish and German show it as the recommended solution.

There are good reasons for this.

1 – Cold Air Sinks. Cold air entering below or behind a heater does not flow up in to the heater as many people wish. A little flows up in to the heater, a little more rises up to envelope bathers feet in cold air, but the majority flows across the floor and then out the exhaust without providing any benefit.

On the other hand, fresh air entering above the heater will get entrained in the upward rising heat and convective loop, disperse throughout the sauna along with that heat and then exit taking CO2 with it.

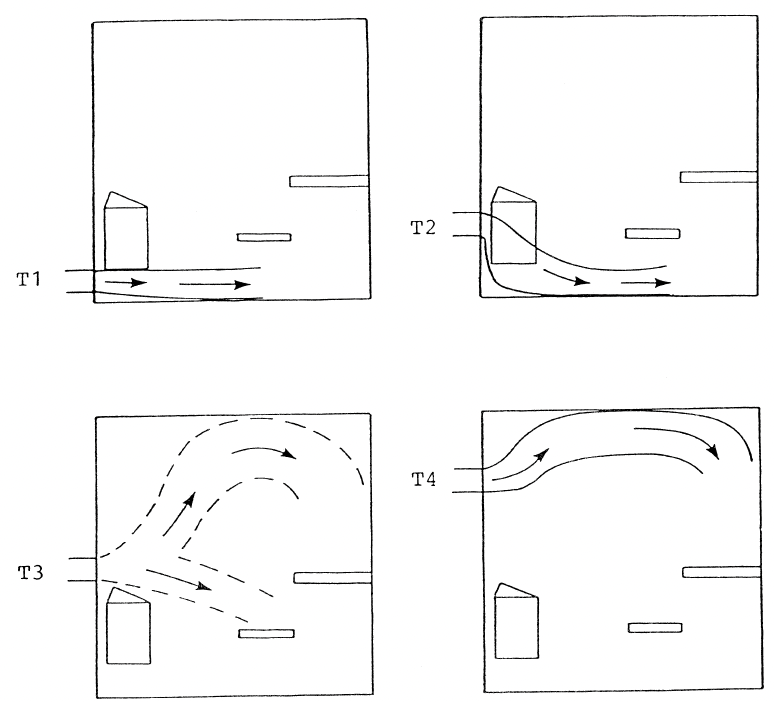

This chart (below) from the 1992 VTT study sums it up well. T1 and T2, which are the recommendations of North American heater manufacturers, simply flow down and across the floor. They provide cooling for the heater but no ventilation for bathers. T3 partially works but not well as a lot of the cold air blows around and through the rising hot air rather than getting entrained in it. In the case of a floor standing heater sitting a few inches away from the wall a portion of the cold air will also flow down to the floor behind the heater, and actually this will be the case for any vent that is not above where the heat plume expansion meets the wall.

T4 is the only supply solution that results in proper ventilation for occupants. There are two reasons for this; 1) It is above where the rising plume has spread out and meets the wall and 2) is high enough that the colder air that begins to sink down will be more likely to get entrained in the rising plume.

2 – Natural Convection Is Unreliable. Any kind of natural convection in an electrically heated sauna is unreliable and rarely if ever results in enough air flow for a healthy environment and sometimes zero airflow. In a wood fire heated sauna the heater itself provides sufficient exhaust airflow but electric heated saunas (and wood fire saunas with external combustion air) need a blower to sufficiently and reliably exhaust stale air.

Natural ventilation is romantic but it only works with wood heaters that pull combustion air from within the sauna hot room. Stale air is not romantic.

3 – Updraft Is Undesirable. Any Updraft Ventilation, natural convection or mechanical, that pulls cooler air upwards results in lower temps for the foot bench. The most critical problem here is that foot benches in these saunas then do not maintain high enough temperatures (minimum +55°c / +130°f but ideally +65°c / +149°f) to kill bacteria and mold. And, while not as important as maintaining healthy CO2 levels or killing bacteria, this also results in cold feet and legs.

Updraft interferes with the convective loop that creates the löyly cavity. This increases stratification which we don’t want and also reduces or sometimes totally eliminates steam (the final element of löyly) reaching bathers. We want steam to follow the convective loop; rise above the heater, flow across the ceiling and then down on us fully enveloping us from head to toe. An updraft is flowing against this and just carries the steam out of the upper vent.

Since our mouths and noses are up high, Updraft ventilation is also pulling whatever is down below up for us to breath. That’s not very pleasant.

Downdraft Ventilation that works with the convective loop pulls warmer air downward, does a better job of removing exhaled CO2, is much more likely to maintain the temperatures needed for killing bacteria and mold in foot benches, is providing cleaner and fresher air directly to bathers, results in warmer and more comfortable legs and feet and enhances rather than reduces the steam that’s so critical to löyly.

This is why everything I can find in Finnish, Swedish or German recommends supply above the heater (not below as everything in English says – and physics is the same in countries that speak English and those that speak other languages).

4 – Ceiling or High Wall Exhausts Kill Löyly – An exhaust in the ceiling (or really anywhere above the foot bench) exhausts steam and heat, quickly killing any löyly before bathers can enjoy it. A high exhaust vent is good for clearing humidity after the days’ session is done, not good for use during sauna.

More

If you just can’t get enough technical stuff… Otherwise skip down to Two Temperature Sensors in North America.

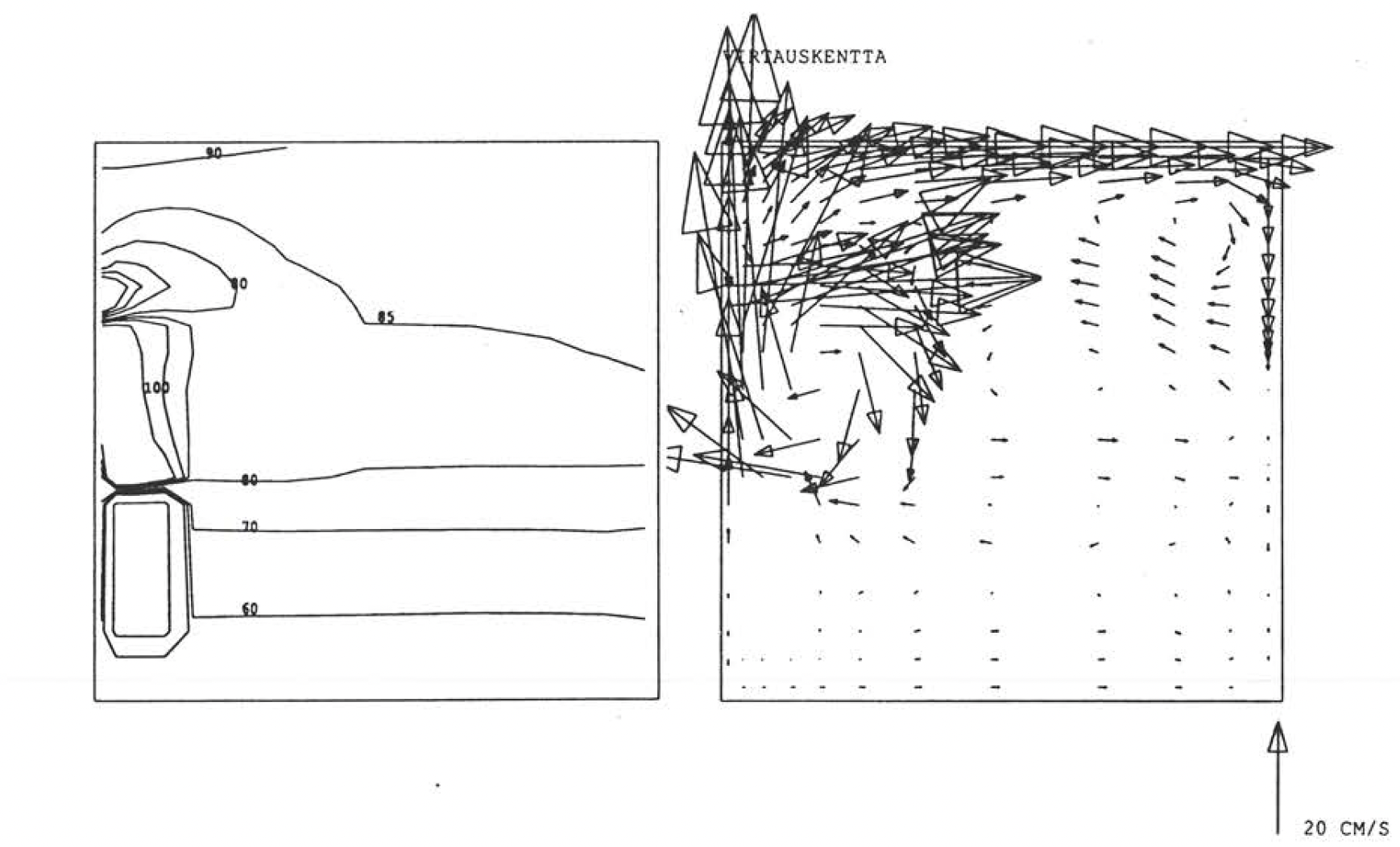

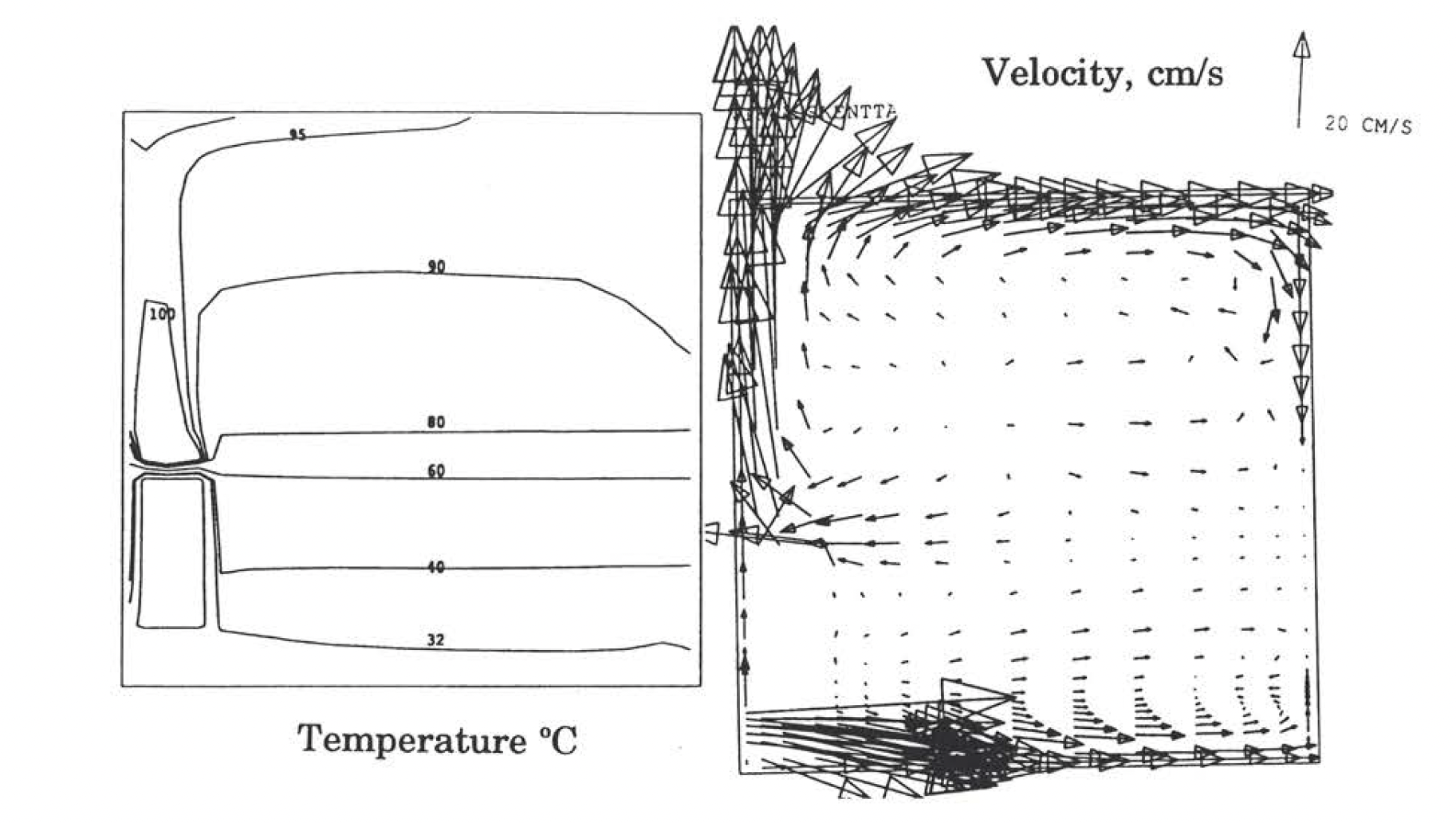

From a follow-up VTT report. The top image below shows air flows and resulting temperature stratification for a supply above the heater (about halfway between the top of the stones and the ceiling) and exhaust high on the opposite wall. First note that there is a lot more air movement (right image) above the heater than below. While there is a convective loop of air flowing down (far right), across the floor and then up through the heater, there is much more air movement higher up.

Second, note the temperatures in this sauna (left image) and how much less stratification there is above the top of the stones than below.

This second image (below) is a typical U.S. sauna with fresh air entering below the heater. Note that here the supply air is, as we’ve seen before, simply flowing across the floor and then eventually to the exhaust vent without providing any benefit of any sort. Only a very little rises up through the heater.

Now, note the temperatures in this sauna vs the one above. Much greater stratification, particularly near the top of the stones. With proper ventilation (above) feet just above the stones are only about 10°c difference from bathers heads – that’s good. Feet just below are already down to 70°c and a 20°c head to toe difference. In the sauna below with fresh supply below the heater feet just above the stones are already about 20°c or more below head temp so twice the difference as above. Feet just barely below already have greater than a 35°c head to toe difference.

Even bathers with feet above the stones will experience colder feet but any feet below the top of the stones will be very cold and a foot bench below the top of the stones will have an ideal environment for bacteria growth rather than killing temps.

Most important though is that this is not providing ventilation – removal of CO2 and other contaminants – nor fresh air to bathers so this sauna will feel more stuffy and bathers are more likely to experience light-headedness or dizziness.

This is the same physics of stratification as the stratification chart from Trumpkin’s Notes on Building a Sauna depicts.

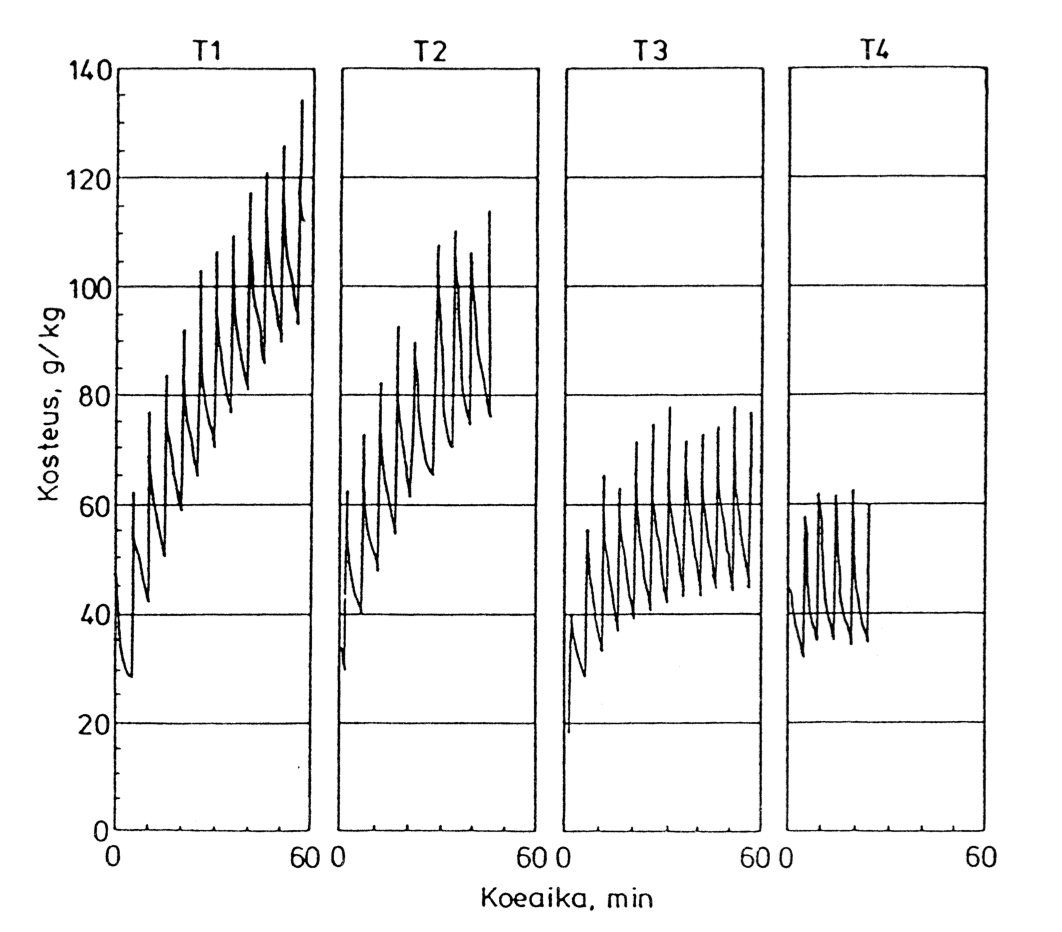

One more interesting chart. This is from the original report and shows humidity (moisture in g water vapor / kg air) for the four different supply locations. This is over a 60 minute period with water thrown on the stones every 5 minutes.

T1 (typical U.S. below the heater) indicates increasing humidity throughout the time period and so little or none removed by ventilation. T2 (behind heater) removes a bit more, T3 (immediately above the top of the stones) more yet and T4 (halfway between top of stones and ceiling) does the best job. T1 will be the least comfortable sauna while T4 the most comfortable.

And as humidity goes, so goes particulate matter. Bathers in a T1 sauna are breathing a lot more particulate matter than those in a T4 sauna.

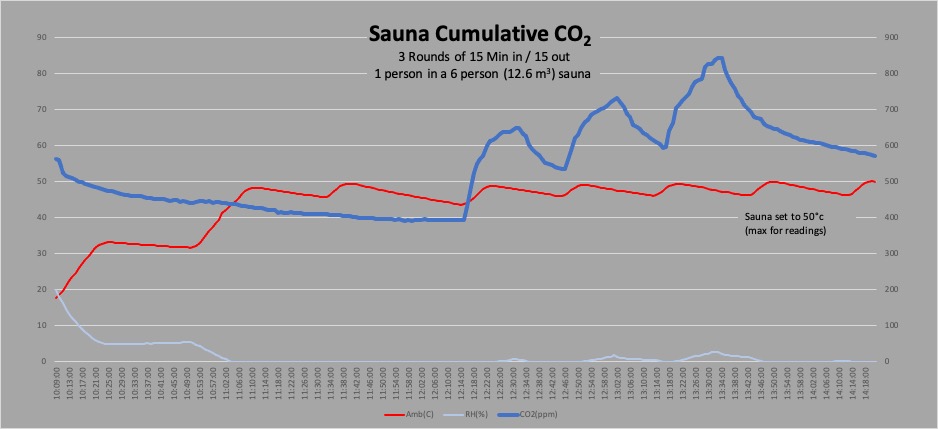

Not surprisingly, CO2 concentrations show a similar pattern. Below is CO2 in our sauna with supply below the heater (T1) as instructed by Tylö-Helo. Even with just me in our 6 person sauna the CO2 levels continued to increase similar to humidity. When I would leave the sauna for 15 minutes the CO2 will slowly decline but not to the level it was before so each succeeding round resulted in ever higher levels of CO2. This is obviously much worse with more people.

Two Temperature Sensors In North American Saunas (Electric)

It’s important to understand that there are two different temperature sensors in North American saunas with electric heaters; A Thermostat Sensor for room temp and a High-Temp Sensor (or High Limit or HL or HT or Thermal Safety or Overheat Protection or Overtemp protection).

Thermostat Sensor – The first is the thermostat that controls the overall temperature of the sauna. In North America the thermostat sensor is often mounted on the wall somewhere above the heater. UL states that the temp in a sauna cannot go above 90°c or 194°f. The Thermostat Control is typically mounted on the wall outside of the sauna or on the face of the heater – it is how you adjust the desired temperature. It uses the Thermostat Sensor to know what the sauna temp is and then turns the heater on/off as needed to stay close to the desired temp.

High-Temp Sensor – This is typically mounted on or inside the electric heater. When this senses heat levels above its set point (about 350°f on our Himalaya) it will trip the HL Switch (High Limit Switch or Overheat Protection Switch or Thermal Protection Switch) and shut off the heater. This requires waiting until the HL Sensor cools below the set point and then resetting the HL Switch (usually a button near the bottom of the heater). This is the sensor that most often causes tripping problems for electric heaters in North America. This sensor is a UL requirement for North America and is not present on heaters in Finland, Sweden or elsewhere.

Confusion, Controversy And Problems In North America (Electric)

Given the overwhelming benefits of Mechanical Downdraft Ventilation (#3) and the critical drawbacks of the other two, why would anyone recommend #1 or #2?

And, why do Tylö-Helo, Harvia and others recommend Mechanical Downdraft everywhere but North America? Last I checked physics is the same in North America as in Finland.

The reason for their recommending supply air below the heater instead of above is to provide cooling for the heater itself – for the High Temp Sensor. The cooler air from a vent behind or below the heater is needed to cool the HT sensor as otherwise it will trip prematurely and shut off the heater until it cools down below the set point.

Heaters sold outside of North America do not need a lower vent to cool the heater or HT sensor nor do they have problems with these tripping unnecessarily. Importantly, electrically heated saunas outside of North America also get much hotter than those in North America (because of UL restrictions in North America) so if anything they should have a greater need for this lower vent yet they do not have one.

There is clearly a major difference in heaters sold in the U.S. and those sold in Europe and it’s a difference that is a significant disadvantage to U.S. consumers and our health.

That I can think of there are only two reasons for the High Limit switch to trip at such a low temperature for U.S. heaters; 1) A UL requirement or 2) Low quality manufacturing. Both are reasonable.

Underwriters Labs, UL, does a lot of good and their recommendations, at least on the surface, result in a safer world for all of us. We do know that they require a very low overall sauna temp of 90°c (or actually well below this) for electric heaters so it is not unreasonable to assume that they also have other regulations that result in manufacturers including the high limit or overheat protection switches that are causing our ventilation (and other) problems**.

U.S. consumers have a reputation for prioritizing lower cost over better quality and of not demanding higher quality – throwing the baby out with the bath water. This would not be the first time that lower quality products are sold to U.S. consumers vs those sold elsewhere. Lower quality have a lower manufacturing cost that results in higher profits. Lower quality also results in shorter life-spans and so higher sales of replacement products. What’s not to like – for vendors. A lower temp setting on the HL Sensor in heaters sold in North America will also reduce warranty liability and the costs associated with that which also helps profits.

I have not yet been able to verify either of these. In my discussions with UL I have yet to see anything from them that would require the low HL switch temp. Heater manufacturers insist that those sold in the U.S. are the same quality and often the exact same heaters as those sold in Finland and Europe (except for anything needed to meet local code requirements). Yet, there is a very clear difference.

To summarize, it appears that the very low set temp for the High Limit switch causes a need for supply air to cool the heater or HL sensor. Manufacturers then chose a solution in North America to provide this cooling to the heater rather than provide ventilation to occupants. This results in high levels of CO2 and other problems for North American saunas.

Another problem is that people, understandably, find workarounds to these UL restrictions to eliminate nuisance trips of the HL sensor and so that their sauna’s can get to the same temps as sauna’s elsewhere.

1) Very often people locate the thermostat sensor much lower than head height so that when the thermostat reads 194°f the actual temp at head height is perhaps 224°c.

This is risky if someone thinks that they’re getting in a 194°f sauna but are getting in a much hotter sauna instead.

There is a similar problem in that the placement required by UL results in actual sauna temps much lower than indicated so an American who thinks they like 190°f (based on a thermostat sensor placed according to UL regs) are actually in a 170°f sauna and are then surprised at what an actual 190°f sauna is.

Finally, temps vary less at lower levels in the sauna so a thermostat sensor placed lower results in greater variability at head height and can result in extremely high temps.

2) People will also often move the HL sensor away from the heater so that it stops tripping. If this sensor is indeed needed rather than only a spurious UL requirement then this increases risk.

Ultimate Solution (Electric)

We need to be able to use the same ventilation as Finland and others with fresh air entering above the heater and uncomplicated by the need to also cool the heater or HT switch. This will likely require either changes from UL, changes by manufacturers or both to eliminate the need for cooling the heater or HT sensor. This is being worked on so hopefully we’ll have better options soon. (Jan 2024 Note – Changes from UL to align better with international standards appear to be nearing completion.)

Proper Ventilation For Saunas in North America (Electric & Wood Fed From Outside)

Note: For saunas that do not have a UL mandated high temp sensor with a very low trip point the lower vent can be ignored.

Until we have heaters without high-temp sensors and can do the same ventilation as others we need to make some compromises with a bit of a hybrid approach. The following applies to electrically heated saunas and most wood heated saunas that are loaded and receive combustion air from outside of the sauna hot room (typically the changing room). Wood heated saunas with loading and combustion from within the hot room have some slightly different criteria discussed further down.

Natural Convection Doesn’t Work Well – If you have an electrically heated sauna you realistically need mechanical exhaust using an electrically powered duct blower or similar. Combustion in wood heaters provides exhaust for wood burning saunas, electric heaters do not. Natural convection requires Updraft ventilation and so comes with the problems of that we discussed above.

That said, you can certainly still do natural updraft if you desire. Thousands of saunas in Finland built prior to the 1990’s were done this way and they are still reasonably good saunas. Just not as good as more recent builds that use mechanical downdraft ventilation and so have fresher air and less uncomfortable stratification.

20-25 CFM Per Person – We want to keep CO2 levels for bathers below 700 ppm and ideally below 550 ppm. Or not more than 150-300 ppm above outside ambient CO2 (typically 420 ppm). A general recommendation is a minimum of 20 CFM (30 m³ / hr) per person (DIN1946 says that 18 CFM are needed but that is in a large space). Due to higher levels of CO2 in exhaled breath of active people however gyms often require 20-30 CFM per person so sauna’s may similarly need somewhat more but this needs more study. Initial measurements in our sauna show a need for somewhere between 20 and 25 CFM per person to keep CO2 levels at appropriate levels. It’s important to note that too much ventilation can lessen löyly by removing too much heat and moisture so the amount of ventilation may need careful balancing.

Also, in North America you need some additional airflow (15 CFM?) through the lower supply vent for cooling the high temp sensor (except possibly for those who’ve moved it away from the heater).

Fresh Air Supply ABOVE The Heater – Air for ventilation needs to enter in a way that it sufficiently mixes with the hot air and circulates to bathers faces. In a well sealed sauna a passive fresh air supply vent with a baffle above the heater/stones, about 2/3 to 3/4 of the distance from the top of the stones to the ceiling will usually work well. This supply may need to be adjustable to insure adequate air to cool the HT sensor.

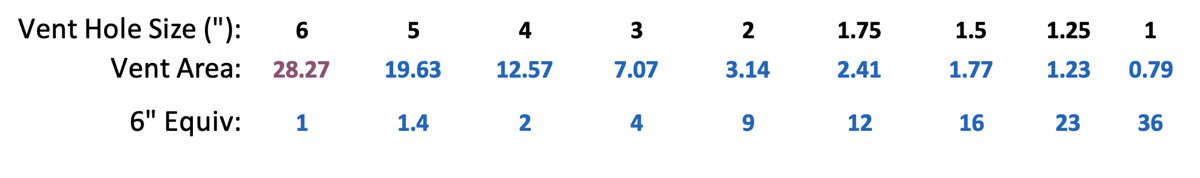

Total opening for this for a 4 person sauna should be about 25 square inches (approx 6” round) but it need not be a single round or rectangular vent. It can be a decorative pattern so long as it has enough opening for air to flow through and aligns with the rising plume from the heater. Similarly, a baffle out in front of it can be decorative and have decorative openings so long as the result is the fresh air mixing with the rising plume and not blowing through it or to the sides of it.

Examples:

Lower static pressure for passive supplies is critical to good functioning so a larger vent, like 7” or 8” instead of 6″, reducing the number and degree of elbows and insuring greater openness in grills are all beneficial.

To prevent this from back flowing, such as when the door is opened, you can include an updraft duct – have the supply duct run upwards to the vent for a bit. Hot air rises so it is then less likely to back flow downward in the duct. A backdraft damper can also help either alone or in combination with an updraft duct. A good source for these is Tamarack.

In some cases such as a sauna that is not sealed well or larger saunas where the door is frequently opened this may require a mechanical blower to work well. This blower should match the exhaust blower and provide the same airflow (typically run at the same speed) so that it provides balanced ventilation. One additional advantage here is that the fan curve for both blowers is then less important so less expensive blowers can be used successfully.

This can also be in the ceiling above the heater. If you do this then you should install some form of back flow to prevent this from becoming an exhaust when the mechanical blower is not running (during heat up, etc.).

Heater Cooling Supply Behind Or Below The Heater – A secondary passive supply may be needed to cool the heater or HT sensor for electric heaters. The required UL set point for these is too low for the heater to function properly so it is necessary to have some cooler air on it to allow the heater to continue working.

We want as much of the fresh supply air entering the sauna as possible to provide ventilation and so come from the supply above the heater. So, this lower vent should be adjustable so that only what air is needed to provide cooling of the heater or HL sensor comes from this supply while the rest comes from the upper supply to provide ventilation. In some cases it may be necessary to adjust the upper supply vent to achieve enough cooling of the heater. My guess is that in most cases about 20% to the heater and 80% from the vent above the heater for ventilation will work best.

Placement of this can be tricky. The airflow needs to cool the HT sensor. On the other hand, we don’t want a bunch of this colder air just flowing across the floor which it will naturally want to do. If the heater manufacturer recommends behind the heater then all should be good. If the mfr recommends below the heater then cheating this supply up a bit and perhaps so that the middle of this vent is at the bottom of the heater might help to insure cooling of the HT sensor with as little cold air on the floor as possible.

I want to again point out that this heater cooling supply and all of the complications that come with it are not needed in Finland or elsewhere outside of North America. This appears to be strictly an unecessary UL requirement in North America.

Mechanical Exhaust Below The Foot Bench – This exhaust vent should usually be on the wall opposite the heater and under the foot bench. This will help to pull warmer air down past bathers feet and result in a much more comfortable experience. Generally placed in about the middle of the longest bench run but perhaps cheated a bit away from the heater for more even distribution.

Note that for best mixing you want to pull air through the sauna with passive supply vents and a mechanical exhaust, NOT push air in to the sauna with mechanical supply and passive exhaust.

FWIW, we used a Fantech FG-6 #40406 (260 CFM @ 0.2” wc) controlled by a Control4 variable speed motor controller. Set at 67% results in 161 CFM for our sauna given the static pressure in the supply and exhaust ducts and works well for a full house of 6 people. For a single person 25% results in about 30 CFM. Note that this blower is NOT rated for sauna temps.

Alternate: Mechanical From Adjacent Shower Room – An alternative to mechanical exhaust below the foot bench. If the adjacent entry/changing/shower has good exhaust then it’s possible to allow exhaust from under the door. There are a number of drawbacks to this though. It can increase the heat and humidity in the changing/shower area. If another door or window is left open in the changing/shower then there may not be sufficient draw to clear the air in the sauna. That said, Lassi has told me that this is not uncommon in Finland and often works acceptably well.

No Leaks – Ideally you want air to enter only through the supply vents so that the air does what we want; provide ventilation for bathers, remove steam and cool the overtemp sensor. So, no gap under the door (or as little gap as is practicable) or other openings where air can come in. This includes the floor. Some very minor leaks shouldn’t be a problem but larger could be. If the sauna will be leaky then mechanical supply (balanced ventilation) will be necessary.

Fresh Supply Air From Outside – Air from indoors will often have high levels of CO2 and other contaminants, this particularly in U.S. homes. We are already stressing our bodies with heat so we want as fresh of air as possible with as low of CO2 and other contaminants as we can get. In most cases air from outside is best. It’s important that this be placed away from any exhausts on the exterior as you don’t want to pull in the same stale air that’s being exhausted.

Exhaust To Outside. Similarly, it is best to exhaust sauna air to outside as exhausting to inside of a home can result in too high of humidity leading to mold growth. It may sometimes be OK to exhaust to a bathroom that has its own exhaust fan to outside. In this latter case it’s preferable to have the bathroom exhaust interlocked with the sauna exhaust to make sure that it always runs when needed.

Measuring – Knowing where to set a rotary knob or programmed HA system for how much ventilation is important as is knowing how well ventilation is working. A Testo anemometer is a good way to do this. Optionally, making friends with an HVAC tech who can do it for you (and knows how to do it correctly). Measurements should be taken on the outside of the sauna for best results. Ideally the inflows to supplies should equal the outflow from exhaust though often inflows will be a bit less as some air will enter elsewhere.

5 Effective CFM is better than 20 Ineffective CFM – If your heater has difficulty keeping up with cold fresh supply air then reduce the flow rather than move the vent lower. 5 CFM entering above the heater that helps to reduce CO2 is much more beneficial than 20 CFM entering below the heater that does not reduce CO2 levels and adds to cold feet.

Clearing Exhaust In/Near Ceiling? – (Maybe) Include a clearing exhaust in or near the ceiling opposite from the heater and supply air. After the day is done this exhaust can be opened (with the heater still heating) with the blower running for about 15 minutes to clear the sauna of accumulated moisture which will help with keeping mold and bacteria at bay. HOWEVER, I’m not sure that this extra vent is necessary. If you have a supply vent over the heater and mechanical exhaust on the opposite side below the foot bench then when you’re done with your sauna for the day you may be able to simply leave it going (heat and ventilation) for 15-30 minutes and get the same result. It should effectively exhaust excess moisture and, assuming at least 55°c at the foot bench, kill most bacteria and mold. This needs more study.

Update: With the upper exhaust vent it takes about 1 – 2 hrs, depending on outside temp/humidity, for our sauna to return to normal humidity after the days’ session is done. Without the upper vent and using only the exhaust vent below the foot bench it takes about 2-3 hrs. From an energy cost standpoint it costs about $0.01 (1 cent) to run the blower for that extra time. Easy decision for me. Note that with either, if you will not be using your sauna for a while, it’d be a good idea to keep it at temp (foot bench at least 55-65°c) for at least a couple of hrs (or heat it up the next day) until the humidity has fallen so that the heat can kill any latent bacteria and mold that might want to settle in while it’s not in use.

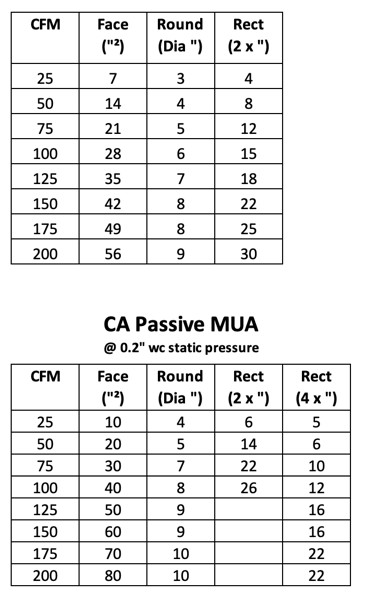

Duct Size/Design – The smaller the duct the more noise from airflow (and the more static pressure) so somewhat larger is generally better. Round duct is more efficient than rectangular so always upsize rectangular duct. Here are a couple of charts for duct sizing for passive ventilation. Face is the total vent opening in square inches.

Every bend, jog, exterior cap, or interior baffle increases the static pressure (resistance to airflow) of the duct which reduces airflow. Smaller duct has greater static pressure than larger duct. So using larger duct and minimizing bends or other deviations can help with airflow. For reference a standard 90° elbow is the equivalent of 30’ of straight duct. A wide sweep 90° is 15’. A wall cap is 15-40’. If you have a very complicated duct then you should ideally do a proper static pressure calculation (or have an engineer or competent HVAC person do it for you).

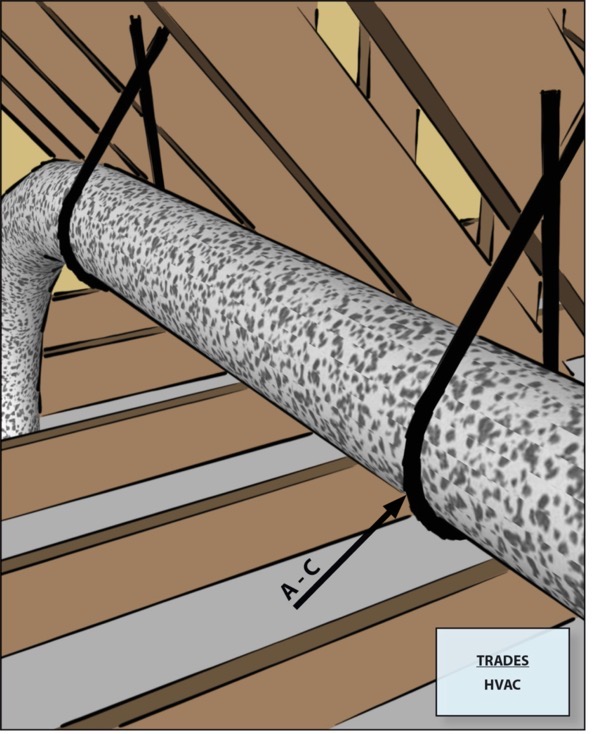

Make sure that the blower and nearby duct is mounted w/ perf strap or isolation hangers and that neither the duct nor blower contact any framing to prevent vibration noise from coming inside your sauna. A silencer (such as from Fantech) installed between your vents and blower can reduce noise a bit more if you want ultimate quiet though proper duct design and installation should result in a very quiet or silent system without it.

Use Hard Duct – Flex duct results in high static pressure, often cannot tolerate the heat of a sauna and should ideally not be used for exhaust ducts. Stretched tight, installed properly and upsized by at least 2″, it’s OK for supply air (and may be a good idea in really cold environments as insulated flex doesn’t have the condensation problems that metal duct does). If you really want to use it for exhaust then oversize by 2” and insure that it’s rated for appropriate temps.

Insulated Supply Duct – In colder environments the supply ducts should be insulated to prevent condensation on them and not a bad idea to do the same w/ exhaust duct.

Blower Size – Blowers are typically rated for how many CFM or m³/hr they deliver. The marketing material for consumer products will typically only publish what is called Free Air Flow which is the blower without any ducting or wall caps that increase static pressure and reduce airflow. If you are familiar with Static Pressure then you should calculate the static pressure losses in your fresh air supply, heat stratification in the stove room, and exhaust ducts. Then choose a fan that delivers the desired CFM @ xx” Wg. However, in most cases you’d likely be safe to simply choose a blower that has about 200-400% of your desired airflow. A variable speed blower and controller are highly recommended.

Muffin Fans / Computer Fans – These typically have very steep fan curves. In other words, it doesn’t take much static pressure to reduce their actual CFM by a great bit. While one may be advertised as 80 CFM, reality when used for a sauna might be only 5 CFM.

With powerful enough muffin fans it’d be possible to use multiple of these. 3, 6 or whatever spread out below the foot bench in a kit sauna could be very effective. Similar to a duct blower these may need to be isolation mounted to prevent vibration noise in the sauna. Some muffin fans have rubber inserts in the mounting holes that provide this function.

Hot Room Volume – Plays a key role in air quality and ventilation. The amount of ventilation needed is primarily based on the number of people because it is exhaled breath that needs to be removed and replaced with ventilation. If we’re ventilating enough to remove exhaled CO2 then we’re likely also ventilating enough to control steam/humidity and other elements.

Greater volume per person has numerous advantages including greater space for natural dissipation of contaminants which makes the air around us naturally much fresher. Similarly, a smaller space requires a much greater amount of fresh outdoor air per volume of space than a larger space. For four people; a 148 cubic foot barrel needs at least the same 80 CFM of fresh outside air as a 260 cubic foot cabin as a 520 cubic foot cabin. The smaller the space the more difficult even mixing is and the more difficult to avoid cold drafts.

Control – Control can be a simple rotary speed controller from Fantech. However, controlling the exhaust blower with something like a Lutron Casetta provides a number of benefits. First is that it will allow for speed control of the blower so that ventilation can be adjusted to balance CO2 removal and heat. It can have a timer to automatically turn ventilation off a certain amount of time after sauna is done for the day. It can be programmed to turn on for some bit of time each day (20 minutes every morning at 7a ?) to prevent musty stale air when the sauna is not in use. On the latter it’s best if this can be done with a smart system of some sort so that it only does this automatic ventilation when supply air humidity will not be too high.

We’ve also played with slowing the blower a bit when the heater is off (heaters turn on and off constantly during use) while using the sauna which has proven very effective in reducing how much cool air bathers feel when it’s very cold (like -30°f) outside. This is fairly easy to do with typical home automation systems such as Control4.

Noise – A mechanical blower can be silent if installed properly. There are two sources of noise; Mechanical Vibration and Air Turbulence. We want to reduce/eliminate these as best we can. Note that a speaker works by mechanical vibration, vibration to the structure of a sauna turns the walls in to giant speakers producing sound. The less vibration, the less noise.

Inline axial fans are generally quieter than inline centrifugal fans but axial can suffer from poor performance and typically have very steep fan curves. If you’ll have very low static pressure in all of your supply and exhaust duct then an axial may be a good option.

A critical and often the primary source of noise is mechanical vibration from the blower transferred to the structure so the first thing to do is to isolate the blower and ideally all of the duct from the structure as best we can. Hanging it with perf strap or isolation hangers so that the blower, silencer and duct doesn’t directly contact the structure is best.

Perf strap looks like: When hanging duct it’s best for the strap to cross over itself once to provide lateral stiffness.

When hanging duct it’s best for the strap to cross over itself once to provide lateral stiffness.

If on a vertical run wrap it fully around the duct at least once (and add a screw if absolutely necessary). Most silencers and blowers can be treated similarly though be careful with any screws in to blowers. Sometimes it’s necessary to use two straps attached to the structure in different directions to suspend everything properly.

The second source of noise is air turbulence. Firstly the tips of the fan blades. A larger blower running at slower speed is usually quieter than a smaller blower at full speed. Similarly, larger duct is quieter than smaller and vent grills with more open space quieter than those with less. A bend in sufficiently large duct to reduce straight line noise can help while each bend in smaller duct can increase turbulence, noise and static pressure. A silencer such as those from Fantech do an excellent job of reducing sound transmission from the blower back to the sauna and are highly recommended. Duct transitions such as smaller to larger or round to rectangular can increase turbulence, noise and static pressure though more in smaller than larger duct.

Ventilation Use

Ventilation (blower) is OFF while heating up. Ventilation is ON while we’re using the sauna and for about 60-90 minutes afterwards to clear moisture.

In our case the time afterwards varies based on outdoor humidity. The higher the outdoor humidity the shorter the run time as once the moisture level in the sauna stove room is equal to the moisture level outside then there is no need to run it further.

It can also run automatically each day for about 20 minutes which is useful for when the sauna doesn’t get used for a time such as when we’re traveling. This is only when outside humidity is fairly low.

Ventilation – Extra Stuff

Multiple Smaller Vents Might Be Best – Ten 2” supply vents (28 sq inches) above the stones might work better than a single 6” as it will result in better mixing (better hot:cold ratio so less of the colder supply air will sink to the floor). Similarly four 3” exhaust vents spread out below the foot bench might do a better job of removing excess CO2 for all bathers than a single 6” that might work well for those directly above but not so well for those further away. For the best even distribution on the latter the vent holes should be slightly smaller near the duct and larger farther away.

I’m experimenting with various configurations in our sauna and the results have been quite enlightening. The current winner for supply is to have about half the supply flowing downward towards the heater and then 5 2” holes horizontally closer to the ceiling. This results in the best mixing and lowest CO2 for different temps and makes for an overall much better sauna experience.

This IR image shows why. You can see how far down the colder air goes at the wall. Eventually though it is warmed enough via turbulent mixing with the rising hot air that it begins to rise rather than continue flowing down to the floor as it would if this vent were nearer the floor. Flowing down like this also aids mixing – if instead it flowed outward as is typical then some portion would flow through the rising heat and might be felt by bathers. A baffle on the supply vent can also help mixing.

Another alternative is a flapper vent cap like those used where exhaust vents exit a house. Holes can be cut in the upper (sloped) face so that when ventilation is OFF the heat rising from the heater will flow up through these holes (and not in to the duct). When ventilation is ON the flap will open and fresh supply air will flow downward towards the heater where it can mix with the rising heated air.

Here’s a quickie chart for the number of holes necessary to achieve a total face area:

Pre-Conditioning Fresh Air Supply – Bringing in very cold outside air for ventilation can sometimes be a problem in some saunas. Sometimes the heater cannot keep up and keep the sauna at our desired temperature and there can also be problems with the air not mixing fully with the hot air and so bathers sometimes feel some colder air mixed with hotter air. Reducing the amount of fresh air is one solution but this can result in poor ventilation and too high of CO2 levels. There are three options that I can think of for heating this incoming air; 1) An electric heater in the duct (such as an Electro Industries EM-WX01), 2) An HRV/CMV that uses the heat in the exhausting air to heat the incoming supply air or 3) A duct running up the wall behind the heater. There are also hydronic duct heaters for situations where there is a supply of hot water from a boiler.

An HRV could be a good option as this would provide balanced ventilation (the same amount of air supply as exhaust) and somewhat pre-heat the supply air. One catch might be finding one that will work with the higher temp/moisture air being exhausted. Braun, Venmar and Build Equinox (CERV) have told me that their units should work in most cases but you should check with them for individual requirements. Some HRV’s made in Europe such as the Finnish Vallox include specific information on using them for sauna.

When sizing it’s important to include air for cooling the HL sensor on the heater (if needed such as UL listed heaters) so for a 4 person sauna you’d want about 125 – 150 CFM actual.

It is also possible to include the sauna in the air exchange (HRV/CMV) system for the house. The key here is to insure that the sauna gets sufficient airflow since it will then be sharing with bathrooms, kitchen or laundry. If this is done both exhaust and supply must be included in the same air exchange system.

Not an ERV – An ERV is designed to maintain humidity but we want the humidity removed somewhat quickly so that we can create a wave of steam again so an HRV/CMV is a better option. The entropy system in an ERV is also more likely to have problems with sauna heat+humidity than the simpler system of an HRV.

Pre-Conditioning Not Such A Good Idea? – In order to produce good steam the stones must remain sufficiently hot. It is not unusual for a sauna to remain hot enough that the heating elements of an electric heater do not turn on enough to maintain sufficient stone temps. Fresh cold air ventilation causes the heater to turn on more often and so keep the stones hotter.

Filtration – Little is mentioned about filtration of incoming air. Generally it is likely not needed. However, during some wildfires in Canada last year we had some significant ambient smoke so I had to rig a MERV-16 filter on to the outside inlet as otherwise the air inside the sauna was quite unhealthy. People in areas with poor air quality may find that a filter on incoming air makes for a better experience. Typically a MERV-13 should be sufficient though a MERV-15 or higher might occasionally be needed.

Supply Side Blower – Ventilation in a space is traditionally accomplished with a mechanical blower on the exhaust side and the supply side being passive airflow (the exhaust blower creates low pressure in the space that then pulls air in through the passive supply duct). Adding a blower to the supply side might help in some situations and could also result in better mixing. Supply side only (passive exhaust) is also a possibility but what happens with airflow in the sauna becomes more complicated. The end result could be better or could be much worse.

Air Circulator – Going a step beyond just ventilation to help reduce stratification and cold feet problems even more. There is one product, Saunum, that attempts to do this. A better option might be doing airflow the opposite of what Saunum does and also incorporate fresh air supply with it. So a duct (3” x 20”?) and blower that runs up the wall similar to a saunum but that pulls in warm room air from behind or slightly above the heater (about 50-100cm or 18”-40” above the floor), mixes it with incoming fresh air, and exhausts it near the ceiling.

Detailed Control – We are playing with a couple of things with control. First is how long the ventilation runs after we are done using the sauna. The higher the outside humidity is the less time it runs. Currently this is just some simple if-then-else programming using outside humidity and a psychrometric chart to set the run timer. We’ve four run times (20, 40, 60 and 90 minutes) and it seems to be working well.

Measurement – Ideally we want to keep CO2 at bathers faces below 700 parts per million and ideally below 550 ppm. Measuring is difficult because CO2 meters don’t work well at sauna temps. We are working with a company on a solution but it’s still a ways out. In the interim there are a couple of options if you want to see how your own sauna does. First is to place a CO2 meter somewhere that temps remain below the max temp for the device (typically 60°c). In our sauna that’s on the platform below the foot bench and a bit away from the heater. Many or most home devices do not provide accurate readings however those from CO2meter.com, IQ Air, and Awair (version 2 or later) have proven reliable. Avoid Foobot. Note that the actual CO2 level at bathers faces is generally a bit higher so adding 10-20% to readings might be good.

The second alternative is to heat your sauna to a temp that is safe for your meter to be closer in proximity to bathers faces and then doing three rounds of ‘cool sauna’. It’s important to find friends willing to do this so that you have as many people as you’d normally have. CO2 is multiplicative so 4 people exhale about 4x as much in to the room as one person.

Troubleshooting

If it doesn’t seem to be working…

As long as your exhaust blower is working properly then it will create a bit of a vacuum in your sauna and fresh air will be pulled in from outside to fill that vacuum. Where it gets pulled in, and getting it pulled in where we want, is a matter of air following the path of least resistance…

First, make sure that the supply vents have as little resistance (static pressure) as possible. Too small of duct, bends, very long duct, flex duct or any obstructions can cause static pressure and reduce airflow.

Keep in mind that lower down in a space is less resistance than higher up (heat rises = stack effect = slightly higher interior pressure the higher up you go = slightly greater static pressure). So:

- If you have a gap under your door then that will usually be the first path of least resistance so close that gap up as best you can unless that is where you are getting heater cooling from and then leave only enough gap for the minimum air you need.

- Next would usually be the heater cooling supply vent which should be open only just enough to prevent the over-temp sensor from tripping.

- Next would be any larger gaps/penetrations lower down.

- And finally would be the fresh air supply over the heater which is where we want air being pulled in from.

Thoughts On Ventilation For Wood Burning Heaters

This is for wood burning heaters that pull combustion air from within the sauna hot room. Here you only need vents for fresh supply air because the heater itself provides sufficient exhaust.

Interesting Background (and why people in Finland are changing how they do ventilation in wood burning saunas) – In Scandinavia, since about the mid 1990’s, ventilation for electrically heated saunas has increasingly been fresh supply air entering above the heater with mechanical exhaust below the foot bench on the opposite side. Over time people began to notice that the air in these saunas was better than that in wood heated saunas and that they felt better. So began efforts to improve ventilation in wood heated saunas with knowledge of the need to introduce fresh air in a way that it mixes better throughout the sauna (e.g., above the heater).

There are two approaches; 1) Fresh supply from below the benches/platforms and 2) Fresh supply from above the heater. And a third option which is to build the sauna with both and experiment to see what works best for your particular sauna.

1) Fresh Supply From Below The Benches/Platforms:

Lassi has recently and rightly begun raising concerns about the potential for back flow with a natural supply above the heater, especially when the door is opened, and some of the difficulties this can cause. This is his version of traditional ventilation with lower supply vents that should not have a back flow problem. I’ve said many times that if there is ever a discrepancy between what I say and what Lassi says, lean towards Lassi – here I’m taking my own advice with perhaps a bit of a mea culpa.

Fresh Air Supply Option 1: Below The Benches Opposite The Heater – Traditionally in wood heated saunas the fresh air supply was via a gap under the door, a supply vent near the heater or via an air permeable floor. Lassi’s idea is to move these to a wall opposite the heater (which provides exhaust) so that the air must flow further through the room and hopefully mix better to provide ventilation to bathers and remove excess CO2.

Fresh Air Supply Option 2: Through An Air Permeable Floor – This can be as simple as air gaps between the slats. Keep in mind that heat rises so though this might seem like it’s a bad idea, it does not cause substantial heat loss in the sauna with proper bench and ceiling heights.

Clearing Exhaust In Ceiling – Typically in the corner opposite the heater. This is kept closed during warm-up and use. Once the day’s sessions are done this vent can be opened (and the vent above the heater closed) to exhaust excess humidity.

Note: From a theoretical psychrometric viewpoint I do not see how this can provide sufficient ventilation to bathers and in particular to effectively remove CO2. There is no mechanism that I can see that will effectively pull stale CO2 laden air from higher in the sauna to lower where it can be exhausted. That said, there may indeed be such a mechanism. If Lassi says that in his experience this consistently provides sufficiently fresh air then I’ll take his knowledgable word on that. Ideally though we should run some experiments measuring CO2 levels to know for sure, particularly since our susceptibility to the affects of CO2 vary and in particular women are more susceptible to higher CO2 levels than men.

2) Fresh Supply From Above The Heater:

Fresh Air Supply ABOVE The Heater – Fresh Outside Air for ventilation needs to enter in a way that it sufficiently mixes with the rising hot air and circulates to bathers faces. A single vent above the stones, about 2/3 to 3/4 of the distance from the top of the stones to the ceiling or placing the vent in the ceiling should work. This should be fully adjustable.

In most cases a passive supply will work though some sauna/heater combinations may require a mechanical supply here.

Combustion Supply Low – This should be sized and located according to; A) manufacturer directions or B) some distance from the heater (e.g., opposite wall/corner). It needs an adjustable vent so why undercutting the door or using gaps in the floor is not appropriate if you want better ventilation for bathers.

Clearing Exhaust In Ceiling – Typically in the corner opposite the heater. This is kept closed during warm-up and use. Once the day’s sessions are done this vent can be opened (and the vent above the heater closed) to exhaust excess humidity.

If you don’t have this clearing exhaust or don’t open it and leave the supplies above the heater open then when the heater stops drawing combustion air the vents above the heater will usually reverse and become exhaust vents providing this function.

General Notes

Balancing – All supply vents should be adjustable. You want about 15-25 CFM per person from the upper supply to provide ventilation for bathers. The rest of the combustion air needed by the heater should come from the lower vent. Depending on a number of variables… it could be that the upper vent is fully open and the lower vent is closed just enough so that the appropriate amount of air is pulled in through the upper vent. Or if the upper vent is pulling too much then the lower vent is fully open and the upper vent is closed until the appropriate amount of air for bather ventilation is entering. This could vary day to day depending on weather and other factors.

The vents do not necessarily need to be changed based on the number of bathers. It should be OK to set them for the maximum number and use that all of the time so long as the sauna can maintain desired temps.

With this approach the upper supply vent can even be completely closed and the lower supply vents used as traditional ventilation so you have both options.

Back Flow Prevention – There are three options for reducing or preventing back flow in a supply vent above the heater:

- Up draft duct prior to vent – A bit of duct that causes the supply air to have to flow upwards prior to entering the sauna will also force hot air to flow downwards in order to back flow. Hot air is very resistant to such downward movement so is less likely to back flow. One option is to have the vent penetration through the sauna wall low and behind the heater with a rectangular duct running up the interior wall to the outlet. This has an advantage in somewhat minimally pre-heating the incoming air. A second option is for this duct to be in the wall cavity or completely external.

- Venturi Vent – There are various vent designs that can create a bit of a Venturi effect that should lessen the likelihood of back flow and also help to pull fresh air in.

- Mechanical Supply – A mechanical supply such as an inline duct blower is an option. Note that air pulled in is likely to mix better than air that’s forced in but the difference may not be significant. Blowers should be mounted in a way that they are acoustically and mechanically isolated to prevent noise.

It’s important that the heater always have sufficient combustion air and not be starved for air.

Pre-Heat Ventilation Air – In colder climates it may be desirable to pre-heat the supply air for ventilation. One option might be something like a 1” x 26” duct (or a 1” x 13” on each side or ??) attached to the back or sides of the heater and extending up about 40” above the top of the stones where the air exits the duct and mixes with the rising hot air from the heater. Better might be to have fins inside the duct that help to transfer heat from the heater to the air.

Outside Intake Low – It may be beneficial to place the fresh air intake lower down to avoid pulling smoke back in to the sauna. Make sure that it’s above any snow depth though.

Note that this is titled ’Thoughts’. Physics says this should all work well but reality may sometimes be somewhat different and I do not have a bunch of wood fired saunas to play with on a daily basis. I believe this approach is still somewhat new in Finland as well so we don’t have the knowledge and experience that we do for electrically heated saunas. More good information is also available (in Finnish so you’ll need to translate) at Lassi’s website saunalogia.fi

Still To Learn:

We see extremely high particulate matter (1.0, 2.5 and 10.0) when ladling water on to the stones. Part of this and possibly all of it is bits of stone breaking off and disbursing with the steam. I’d guess some of it is also from the calrods. Neither is good. As ventilation has improved so has this. Moving the fresh air supply to over the heater had very dramatic effect on lowering PM and better mixing using different hole patterns has helped as well.

We’re still trying to figure out a good reliable way to measure CO2 near bathers faces during a sauna session. It’s easy to do at lower temps like 60°c but not so much at 96°c which is above the temp range for most meters. Airflow will be different then too so why I’d like to find a good way to measure it. We’re currently experimenting with using a longer tube (about 8m) with most of it laying on the floor of the sauna. Pulling air for sampling through this allows it to cool enough to work with a higher temp sensor from TSI.

** Just as with some overly strict laws, overly strict UL regulations can cause more problems than they solve. Saunas limited to 90°c often have problems with bacteria and mold in the foot benches and elsewhere because the sauna cannot get hot enough to kill them. The lower temps also may not result in the health benefits that higher temp saunas in Europe provide. As well, to get around the low limit, many people place the thermostat temperature probe for electric heaters in a location that allows the sauna to achieve higher temps than the 90°c that UL states. One problem with this is that it can no longer properly regulate the temperature as a thermostat outside of North America can. If a thermostat in Finland says the sauna is 90°c then you know it likely is, in North America it may well be much hotter.

The lower temperature setting for the High Limit Switch causes numerous problems. Chief among these is that it’s caused manufacturers to recommend bad ventilation strategies that result in unhealthy levels of CO2 in U.S. saunas.

* Thanks to Lassi Liikkanen for having VTT publish this research online.